Pandemic-driven biotech innovations have revealed a beautiful world of molecular biology filled with abundant promises to cure untreatable diseases. To keep up with the accelerated pace of research, flexible labs will be necessary for our brilliant scientists to access a changing array of instruments as hypotheses emerge and assessments evolve.

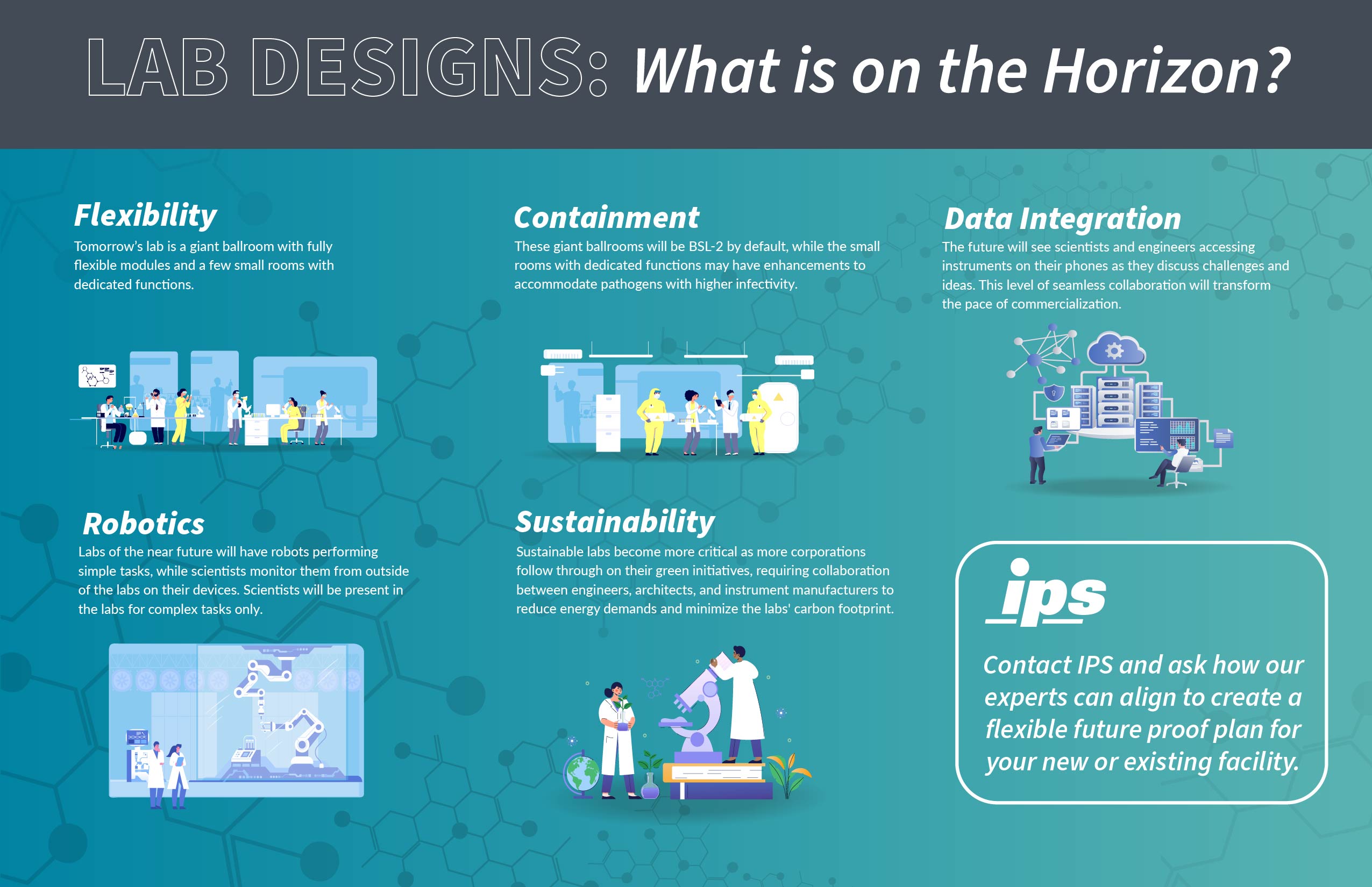

Flexibility

An industry buzzword just a few decades ago, flex labs are becoming the norm rather than a luxury. Building technology has kept pace with this trend. Lab owners, designers, and builders now have multiple options for creating flexible labs. The notion of flexibility extends outside of labs because lab footprints must seamlessly grow and shrink to react to a dynamic demand. Adjacent write-up spaces can be designed using the lab modules so they can be easily converted into labs. Labs of the past were housed inside individual rooms. The labs of the future will be very large ballrooms with modular, flexible set-ups. Only a few labs, such as PCR or sterility, will be in a room requiring special ambient conditions. Tomorrow’s lab is a giant ballroom with fully flexible modules and a few small rooms with dedicated functions.

Containment

Scientists will continue to innovate newer therapies within the biologics and ATMP sectors. The industry will need many more labs where biological agents can be manipulated safely. The majority of the new labs will be designed to support BSL-2 containment. A good understanding of BMBL and NIH guidelines and intuitive knowledge of containment principles by the architect and mechanical engineer will become a must. While the GMP manufacturing environment has significant infrastructure implications for BSL-2 vs. BSL-1 or non-BSL classifications, a BSL-2 lab is not significantly different from a typical R&D lab. Negative airflows, BSCs, wipeable surfaces, and HVAC systems with HEPA filtration are the basic building blocks of a standard BSL-2 lab. Designing basic labs otherwise does not make sense in today’s biologics and ATMP-heavy environment. These giant ballrooms will be BSL-2 by default, while the small rooms with dedicated functions may have enhancements to accommodate pathogens with higher infectivity.

While the innovation pipeline has been robust, the industry grapples with converting it into commercial products. What works magically at the bench scale often fails at the development scale or, at best, scales up to a limited batch size.

Research and product development comes at an enormous cost to the industry. These costs must be recouped with large-scale commercial sales of the drug product. Unless a promising molecule can be developed for large-scale GMP manufacturing, the therapeutic will not be affordable for most of us. A limited customer base means financial failure as it caps total revenue for the manufacturer. The industry will overcome this challenge by fostering intense research and development collaboration. This collaboration will be intentionally cultivated via facility designs encouraging informal meetings between researchers and developers. Scientists working in these flexible ballrooms will randomly and often cross paths with the engineers working in product development labs in the same building. This diverse community of brilliant minds will push the industry forward by accelerating the pace of commercialization through strong collaboration.

Data Integration

Bioinformatics and robotics are both rapidly growing branches of biomedical technology. In addition, bioinformatics will increase the automation and integration needs of lab instruments. IT infrastructure and data integration platforms will gradually become integral to lab planning. The lab of the future will generate more data and demand more storage, creating security needs. There will be a push for remote monitoring of instruments, forcing platform integration and remote access. Finally, building automation systems will integrate into lab monitoring systems. The future will see groups of scientists and engineers accessing instruments on their phones as they discuss challenges and ideas with each other. This level of seamless collaboration, any place, any time, will transform the pace of commercialization.

Robotics

With the advancements in the field of robotics, coupled with growing labor costs and shortages of the high-skill workforce, lab equipment will increasingly use robots to perform simple, repetitive tasks previously completed by lab techs. Labs of the near future will have robots performing simple tasks, while scientists will monitor them from outside of the labs on their devices. Scientists will be present in the labs for complex tasks only.

Scientists and engineers are people, first and foremost, who receive energy and inspiration from within and their surroundings. While old labs assumed a closed-off room would be adequate, the lab of the future will create spaces with daylight, soothing colors, and warm and inviting spaces. Scientists and engineers will be invigorated by their creative surroundings that excite minds with inspiring ideas.

Sustainability

Lastly, a need for sustainable labs will grow in importance as more corporations follow through on their green initiatives. Labs have traditionally been energy hogs due to high air changes and the need to maintain strict ambient conditions, housing instruments with significant cooling and heating loads. Bio-safety cabinets, fume hoods, refrigerators, fridges, and incubators will continue to reside in labs, stretching and straining the mechanical systems’ limitations. Engineers, architects, and instrument manufacturers will increase collaboration since reducing these energy demands will be crucial to minimizing the labs’ carbon footprint.

Contact IPS and ask how our experts can align to create a flexible future-proof plan for your new or existing facility.