By Christopher Hall- Director, Process Architect

Figure 1: uCity Square, ZGF Architects LLP Figure 2: Gene Therapy Laboratory

The growing expansion of gene therapy research in urban laboratory facilities presents a tremendous opportunity for high-throughput bioreactor applications. Recent advancements in bioreactor automation have improved lab efficiency and provided a critical experimental advantage in early discovery and process development work. These high throughput bioreactors can reduce risk while simultaneously affording greater scalability potential in the run-up to full manufacturing process designs.

From a laboratory design standpoint, two particular challenges should be considered when integrating bioreactors. First, space availability in an urban setting can limit laboratory footprint configurations -- placing a premium on equipment layout efficiency. Next, building code limitations exert a considerable challenge in providing a continuous and reliable high-purity oxygen supply for bioreactors. This article will explore the interrelationship of high-rise laboratory design applications as they apply to bioreactor use.

Figure 3: Automated Bioreactor

Design of Experiment Opportunities

The latest high throughput bioreactors provide innovative process development opportunities for today’s gene therapy lab users through the Design of Experiment process (DoE.) Rather than testing individual experimental values manually, the DoE approach allows for the construction of a set of representative experiments which explore multiple variables simultaneously. Experiments are interrelated and can provide valuable data in support of decision-making.1

Using a series of automated bioreactors, the high throughput system allows for faster, cheaper experimentation that reduces the capital-intensive risk associated with smaller volumes. This rapid and reliable model can explore a wide range of testing conditions that can then be scaled to larger bioreactors.

The enhanced experiment design capabilities help minimize run failures – and the resulting hours lost re-running experiments -- that can hinder traditional benchtop reactor activities, especially by reducing the human error associated with manual liquid handling. The DoE process dramatically improves scientist scheduling, idle times, and long set-up times, which allows scientists to focus work elsewhere in the lab.

Increasingly, automation has proved a necessity in modern laboratory design. Improved productivity and accuracy, as well as drastically-reduced experiment run times, allow for 24/7 operation with reduced staffing burdens. This marked improvement in efficiency can ultimately accelerate the rate of progress to larger pilot studies and manufacturing- scale work. DoE applications can substantially shorten run times by up to 80 percent over traditional bioreactors.2

From an architectural perspective, the high throughput design provides a substantial footprint reduction over traditional bioreactor configurations, which increases the overall equipment space available to the laboratory. Since automated bioreactors considerably reduce failure rates, this new technology can also optimize research efforts by generating more reliable data and eliminating the risk of process development bottlenecks. As a result, the related cost savings can be substantial.3

Figure 4: Laboratory Gas Cylinders Figure 5: Automated Bioreactor Utility Rough-Ins

Building Code Challenges

To operate successfully, bioreactors require high-purity, oil-free filtered oxygen. This is problematic in a high-rise gene therapy laboratory environment since building codes greatly restrict the capacity to store oxygen above the first floor. While oxygen consumption varies by experiment and run-time, high throughput bioreactors effectively require a limitless oxygen supply. Of course, this presents an obvious fire hazard.

In comparison to identical ground-level facilities, the building code allowances for high rises above the sixth floor are only 5% of the maximum allowable quantities (MAQ).4 In the event of a fire, the building code limits on MAQs protect occupants as they flee the lab and enables firefighters to access the area safely.5

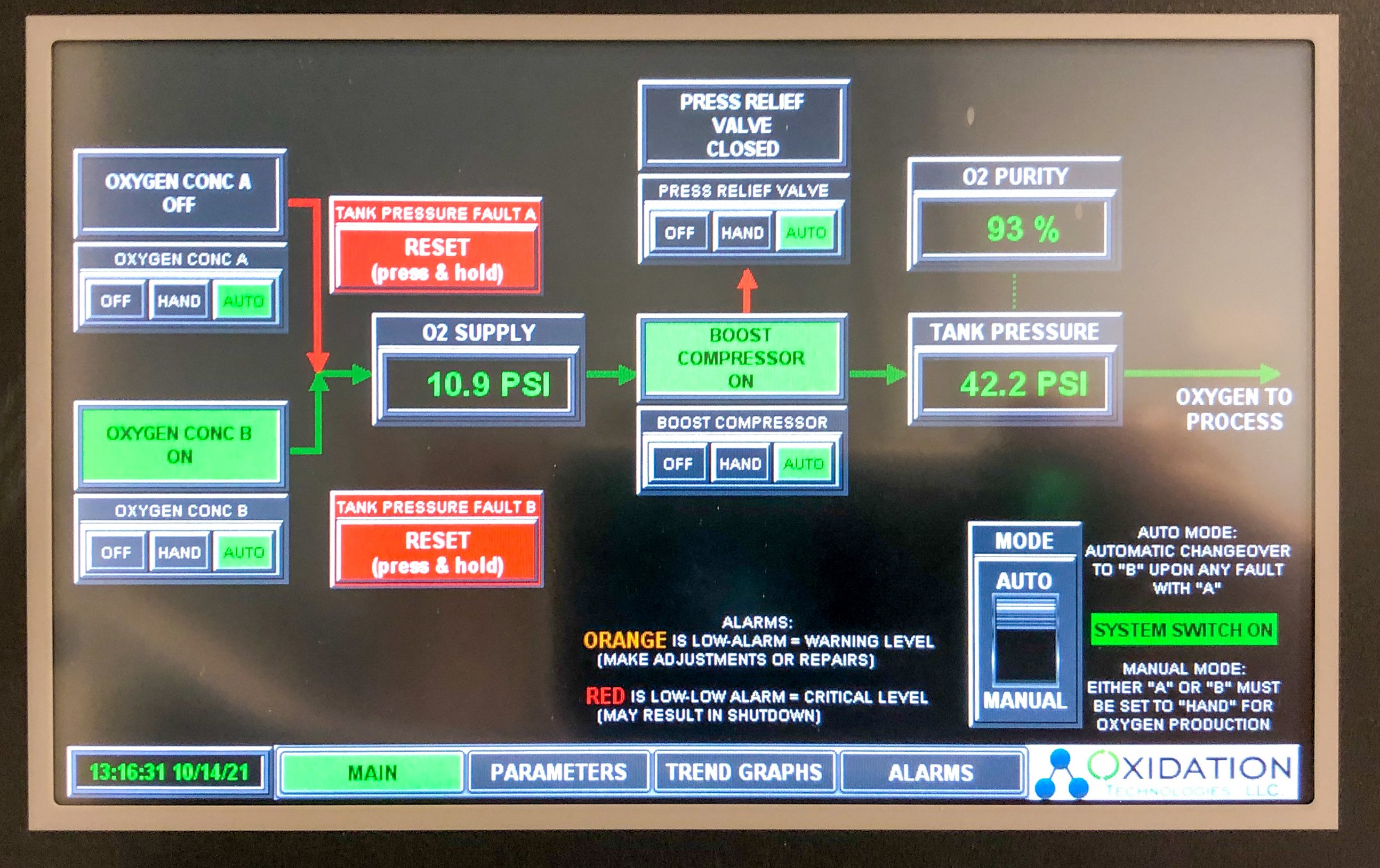

Figure 6: Oxygen Generator System Figure 7: Oxygen Generator System, HMI Control Panel Display

Oxygen Generator: High-Rise Building Solution

Given the restrictive nature of high-rise oxygen storage and the need for reliable, high-purity oxygen supply for high-throughput bioreactors, a robust oxygen generator system provides a viable solution to meet all code and gas supply parameters. As can be seen in Figure 6, the generator system includes several components:

- Oxygen Generators: 1 primary + 1 backup

- Oxygen Purity Recorder

- HMI Control Panel: constant reading and data logging, trend graphing

- PLC Controller: provides auto switch to backup unit in the event of failure

- Oxygen Buffer Tank

The equipment assembly provides a backup generator that will engage in the event of primary oxygen generator failure. The oxygen purity recorder provides constant monitoring of oxygen production to meet the bioreactor system requirements. The HMI (human machine interface) control panel shown in Figure 7 provides real-time system status and data display. The generators are capable of producing 93% pure oxygen at 10 liters/minute flow rate and are connected to a UPS and backup generator to accommodate power failure.

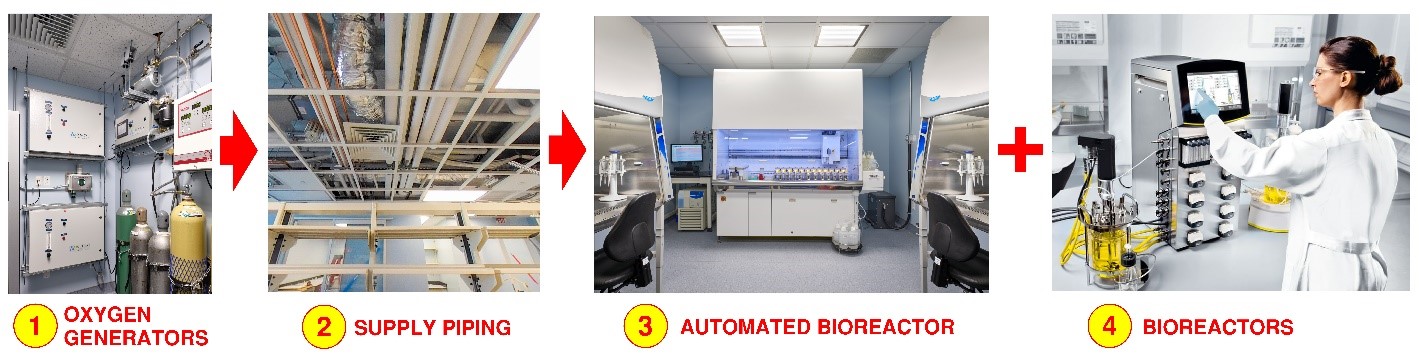

Figure 8: Oxygen Generator and Bioreactor System Flow Diagram

Architectural Design Solution

The elimination of oxygen cylinder storage within the lab footprint offers a new level of design flexibility in high-rise building applications. While the safety advantages of oxygen generation systems are substantial, these systems also improve workflows and eliminate the time-intensive need to store and manage oxygen cylinders throughout the lab.

The recent design and construction of a gene therapy lab on the ninth floor of a high-rise building in the University City area of Philadelphia illustrates the advantages of integrating high throughput bioreactors with oxygen generators. An aggressive research and process development program utilized this combination to great effect within a limited lab footprint.

Figure 8 illustrates the oxygen supply flow strategy for the facility. The oxygen generator system (1) is co-located with other lab gas cylinders and a UPS system in a small utility room. A ¾-inch copper supply line (2) connects the oxygen generator system to an automated bioreactor (3) and traditional benchtop bioreactors (4) located at the opposite end of the lab space in a process development work area.

Strategically, this configuration provides several design advantages. By locating the utility room outside the formal lab boundary, maintenance staff are able to perform any service functions without interrupting lab workflows within a BSL-2 environment. Placing the oxygen generator within a remote utility space acoustically isolates any operational noise from lab personnel within the working lab area. Tethered by above-ceiling gas supply lines, the bioreactors can be strategically located within the lab to maximize workflows.

Figure 9. Cell Culture Lab

Conclusion

The use of high-throughput bioreactors offers a number of performance and lab configuration advantages, but their use might be complicated by the need for a constant supply of high-purity oxygen to execute experiments. As high-rise lab construction grows to meet increased biotech demand within major metropolitan areas, the economized footprint of this new equipment will allow for greater design flexibility over traditional bioreactor configurations. However, building code restrictions on oxygen storage can impede lab programming and functionality in the upper floors of a tower. Within this context, oxygen generators can provide a reliable oxygen source to these platforms while offering greater design flexibility throughout the facility

Orignally published in Pharmaceutical Engineering