You’ve decided that you want to modularize elements of our new facility. The benefits --better cost control, reduced schedule, and transfer of risk away from our jobsite -- are too great to ignore. So how should you go about it? What changes do you make to your engineering, procurement, construction, and compliance processes to maximize the benefits of modularization?

In the past, modularization efforts were undertaken after the design process was complete, using construction documents as input information. This approach yielded some benefits, but it generally optimized the construction process given the specific constraints of the design as depicted in the construction documents. This process evolved as the need to benefit from modularization increased and constructors became more knowledgeable and aggressive in pursuit of efficiency. Eventually, constructors began modifying designs to maximize modularization, and owners accepted this approach because of the significant benefits.

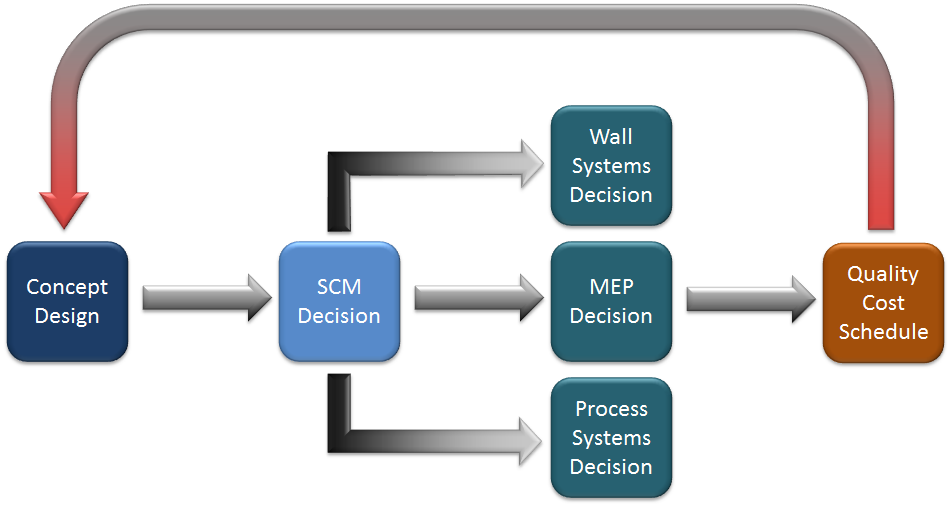

Not to be outdone by their construction industry brethren, designers have modified their processes to include a modularization step early in the project life cycle. Today, most designers develop a concept for a new facility, and immediately study the modularization options for the project to ensure that subsequent design phases accommodate modularization objectives. The process that is typically employed today is depicted in the following diagram.

This process is iterative; the function of the facility is defined in a conceptual design study, then modularization options are generated, the impact of those options on cost, schedule, and quality are is evaluated, and the facility design is adjusted to take advantage of the selected modularization decisions. This approach can achieve much of the desired benefit of modularization, but it has some obvious flaws. Can the iterations be eliminated? Can modularization be built into the conceptual design?

This article originally appeared as a supplement to the 2015 IPS Technologies Tours at INTERPHEX.